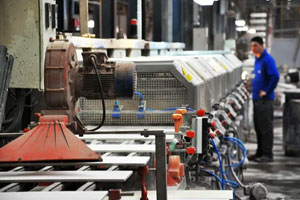

Manufacturing Process

The main raw materials used in decorative wall tile production are the clay, feldspar, kaolin, quartz, and other minerals. These materials are mined, crushed, and screened to remove impurities.

The raw materials are mixed in a precise ratio to create the tile body. Water is added to form a slurry, which is then passed through a filter to remove any remaining impurities.

The slurry is poured into molds and pressed to remove excess water. The tiles are then left to dry for several hours.

Once the tiles are dry, they are coated with a layer of glaze. This glaze gives the tile its decorative finish and provides protection from moisture and stains.

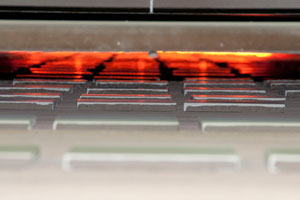

The glazed tiles are then fired in a kiln at high temperatures, typically between 1100 and 1300 degrees Celsius. This process fuses the glaze to the tile body and makes the tile durable and resistant to wear and tear.

Once the tiles have cooled, they are inspected for defects and then cut to the desired size and shape. The edges are finished to create a smooth, even surface.

Finally, the finished tiles are packaged and shipped to distributors or retailers for sale.