Manufacturing Process

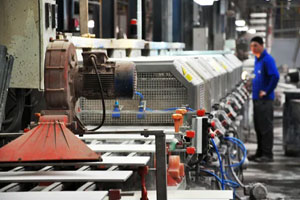

The main raw materials used in the production of third fire tiles include clay, feldspar, quartz, and other minerals. These materials are sourced from suppliers and checked for quality and consistency.

The raw materials are mixed together in precise proportions to create a homogeneous mixture. Water is added to the mixture to create a slurry.

The slurry is then pressed into molds that are designed to create the shape and size of the tiles. This process involves applying pressure to the slurry to remove excess water and create a dense material.

The tiles are left to dry in a controlled environment for a specific period of time. This allows the excess moisture to evaporate and the tiles to harden.

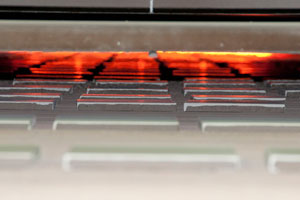

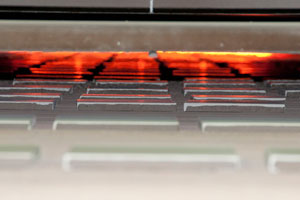

The dried tiles are fired in a kiln at high temperatures to create a bisque or unglazed tile. This process removes any remaining moisture from the tiles and creates a strong and durable material.

Once the tiles have cooled, they are inspected for defects and then cut to the desired size and shape. The edges are finished to create a smooth, even surface.

The glazed tiles are fired in a kiln again at high temperatures to fuse the glaze to the surface of the tile. This process creates a smooth, glossy finish and ensures that the glaze is durable and resistant to wear and tear.

Once the third fire tiles are finished, they undergo rigorous quality control checks to ensure that they meet industry standards for durability, appearance, and performance.

Finally, the tiles are packaged and shipped to distributors or retailers for sale.