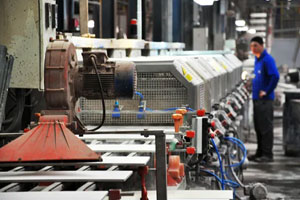

Manufacturing Process

The main raw materials used in the production of step and riser tiles include clay, feldspar, silica, and other minerals. These materials are sourced from suppliers and checked for quality and consistency.

The raw materials are mixed together in precise proportions to create a homogeneous mixture. Water is added to the mixture to create a slurry.

The slurry is then poured into molds that are designed to create the shape and size of the step and riser tiles. The molds are vibrated to remove air bubbles and ensure that the mixture is evenly distributed.

The tiles are left to dry in a controlled environment for a specific period of time. This allows the excess moisture to evaporate and the tiles to harden.

The tiles are coated with a layer of glaze that gives them a decorative and protective surface. The glaze can be applied either before or after firing, depending on the specific manufacturing process.

Once the tiles have cooled, they are inspected for defects and then cut to the desired size and shape. The edges are finished to create a smooth, even surface.

Once the step and riser tiles are finished, they undergo rigorous quality control checks to ensure that they meet industry standards for durability, appearance, and performance.

Finally, the tiles are packaged and shipped to distributors or retailers for sale.